VG-21 Maintenance

Item # 15 15 January, 1995

NOSE

WHEEL SHIMMY: If you own a Varga, you have probably

experienced a nose wheel shimmy at some time. I think the most

The easiest way

to look for nose gear steering wear and tear is to have someone hold the tail

down while you turn the nose gear through it's travel

and check to see if everything is tight. You can also try to move the nose

wheel fore and aft and from side to side to see if the plastic bushings inside

the strut are still in good condition. If anything moves in the wrong direction

(up and down instead of fore and aft, for example) then you should take it off

and examine it's attachment holes and fasteners for

wear. Repair or replace any parts that need it. When you lubricate it and put

it back together, it's probably better to have just a little friction than

totally free movement.

Steering Yoke

Inspection and Repair: The Steering Yoke is kind of a special case. I haven't

seen one yet that didn't need to be shimmed a little. Making a shim isn't hard

(I usually cut up a beer or pop can) but you must remove the lower strut to

install it. This removal procedure is described in paragraph 6.4.1 of the

maintenance manual. Worn shimmy dampener, torque link and steering arm

attachment holes can usually be drilled oversize and bushed by you or your

repair shop.

Shimmy Dampener

Inspection and Repair: The shimmy dampener was not made to be disassembled, but

I finally figured out how to replace the push rod "0" rings which are

the most

Before removing the shimmy dampener assembly,

check the rod end bearing, rod end bearing to yoke attachment bolt

and hole and the

cylinder attachment bolt and hole for excessive play. If the Spherco TRE-4 rod end bearing is

worn out,

get a new one. If the

NAS 1297-4D-12 shoulder bolt is worn, get a new one. If the attachment hole on

the shimmy

dampener is worn,

it will probably have to be taken to a shop and bushed and reamed to the proper

size.

Remove the shimmy dampener from aircraft.

Clean the dampener assembly thoroughly to

remove all dirt, grease and hydraulic fluid.

Remove 12-24 x 1/4" filler screw (Don't

lose this screw, they are hard to find!) from dampener. Inspect the fiber

washer

for condition and

replace if necessary.

Push the rod end bearing all the way in (as

close to dampener cylinder as it will go) and fill the cylinder

aircraft hydraulic

fluid. A large syringe with a large needle works very well for this. Make sure

all the air has been

removed. This may

require overfilling until all air bubbles stop

Reinstall the filler screw and tighten.

Wipe the dampener clean and dry of hydraulic

fluid.

Move pushrod back and forth through it's full

stroke while inspecting to see IF and WHERE hydraulic fluid is leaking out.

Pushrod movement will be jerky or noisy if

there is still air in the dampener. If the dampener isn't jerky, noisy or

leaking,

put it back on the

airplane. If it is not leaking but is still noisy or jerky when you push the

rod back and forth, refill it until

ALL the air is gone. When the pushrod action

is smooth and quiet through it's full stroke put it

back on the airplane.

If the dampener is leaking at the joint

between one of the end caps and the cylinder casting, you will probably need to

take it to a shop

and have the end cap pressed out so that the outer "0" ring can be

replaced. Unfortunately, removal of

the end cap can

sometimes score it and/or the cylinder wall so badly that it won't stay in

under pressure when

reinstalled. You

may have to repair or find or make new parts to fit if this happens. If you must remove an end cap,

make sure before

you reinstall it that the pushrod hole is also in good condition and the proper

inside diameter.

Worn Push Rod

Seals: If oil is only leaking from around the pushrod holes, the following

repair instructions to remove and replace the pushrod "0" ring seals

may work for you.

Remove the oil filler screw and pump or drain

out all the fluid.

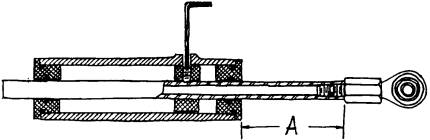

Move the push rod until the rod end bearing

end of the push rod is about 3 1/2" from the center of the filler hole.

The

pushrod piston

should be visible in the filler hole. Rotate the pushrod in either direction

until the piston set screw is

visible and

centered in the filler hole. Install an alien wrench in the set screw through

the filler hole. Measure and write

down or remember

the EXACT distance of the rod end bearing to the end of the shimmy dampener

(dimension "A"). You

will need it for

proper reassembly.

CAUTION! Before loosening the set screw

make sure there are no burrs or sharp edges on the unthreaded end of the

pushrod. lf there are, carefully clean them off with fine emery cloth

or a file or you will risk damaging the inside diameter

of the end caps or

piston when you remove the pushrod.

|

|

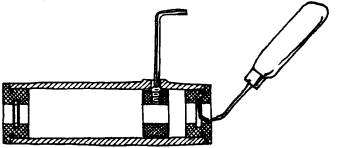

![]() Rotate the allen wrench counter clockwise and

back the set screw out until it gently but firmly contacts the inside of the

filler screw hole. This should hold the piston in place white you gently but

firmly tap the unthreaded end of the pushrod out with a 5/16" diameter

brass or aluminum rod. NOTE: You may wish to hold the alien wrench in the

setscrew hole to help keep the piston from moving out of place while tapping on

the pushrod.

Rotate the allen wrench counter clockwise and

back the set screw out until it gently but firmly contacts the inside of the

filler screw hole. This should hold the piston in place white you gently but

firmly tap the unthreaded end of the pushrod out with a 5/16" diameter

brass or aluminum rod. NOTE: You may wish to hold the alien wrench in the

setscrew hole to help keep the piston from moving out of place while tapping on

the pushrod.

![]() After the pushrod has been removed you will be able to see the

"O''rings by looking into the pushrod holes in

the cylinder end caps. Using a sharp needle-like tool, carefully remove the

"0" ring from its groove in the end cap. CAUTION: Be careful not to

scratch the bore in the end cap or to push the "0" ring into the

cylinder because it may be very hard to get out without removing an end cap.

After the pushrod has been removed you will be able to see the

"O''rings by looking into the pushrod holes in

the cylinder end caps. Using a sharp needle-like tool, carefully remove the

"0" ring from its groove in the end cap. CAUTION: Be careful not to

scratch the bore in the end cap or to push the "0" ring into the

cylinder because it may be very hard to get out without removing an end cap.

|

|

![]() After the "0" rings have been removed, inspect the end

cap pushrod holes for wear or damage and repair as required.

After the "0" rings have been removed, inspect the end

cap pushrod holes for wear or damage and repair as required.

![]() Inspect and clean the "0" ring groove and carefully

install a new "0" ring, again using CAUTION not to push the new

"0" ring too far past the groove and into the cylinder.

Inspect and clean the "0" ring groove and carefully

install a new "0" ring, again using CAUTION not to push the new

"0" ring too far past the groove and into the cylinder.

![]() Before reinstalling the pushrod, inspect the setscrew dimple and

the ends for burrs and/or sharp edges. Remove them with a file or fine emery

cloth as required. Any sharp edges left on the pushrod may cut the

"0" rings when the pushrod is reinstalled and cause premature

failure.

Before reinstalling the pushrod, inspect the setscrew dimple and

the ends for burrs and/or sharp edges. Remove them with a file or fine emery

cloth as required. Any sharp edges left on the pushrod may cut the

"0" rings when the pushrod is reinstalled and cause premature

failure.

![]() Lubricate the "0" rings with hydraulic fluid and

reinstall the pushrod opposite of removal.

Lubricate the "0" rings with hydraulic fluid and

reinstall the pushrod opposite of removal.

![]() Fill the cylinder with hydraulic fluid, check for leaks and smooth

operation and put the shimmy dampener back on the airplane.

Fill the cylinder with hydraulic fluid, check for leaks and smooth

operation and put the shimmy dampener back on the airplane.